Making new things possible and better with Tengjin.

Making new things possible and better with Tengjin.

We started as a plastic and rubber molding company in 2007. Over the years, we have innovated and developed in the industry specializing in engineering, designing, manufacturing plastic, and rubber parts and assembly, and providing high-quality parts for various industries.

We specialize in injection mold tooling, plastic injection molding, rubber compression molding, plastic blow molding, rubber extrusion, and more. We have been helping numerous brands and companies grow up and expand their businesses to new heights.

To provide high-performance custom parts for any industry. Rubber and plastic parts play vital roles in pieces of machinery that are both reliable and innovative. Efficient and affordable, our parts are a balance of simplicity and functionality.

Taking the extra mile for you to experience the best service in producing rubber and plastic molded parts. Making high-quality products for industries needing plastic and rubber molded elements.

Tengjin was founded by several extraordinary founders with ambition and kindness. They are full of enthusiasm, and joined the industry without hesitation to enjoy the fun of making new products and helping companies grow.

"Creating new products is very easy, but creating the exact products right, rapidly and excellently is tough. We love taking on this challenge."

"I love to help customers grow, just as we create and turn design into life. May we be a small stone that contributes to customers' great height."

Our core values comprise honesty, win-win, enterprise, and hard work, to innovate and develop high-performance molded parts for you and your shop. Here are the qualities of Tengjin’s DNA.

We ensure a good relationship with our suppliers and you by providing all the necessary information to check any issue.

While pursuing our own development, we will also strive to serve customers and strive for mutual cooperation, development and win-win.

Tengjin continuously optimizes materials and production processes and is committed to maximizing production efficiency and product quality.

We continuously optimize our materials, equipment and processes, and are committed to providing quality products and services.

From product development, designing, analyzing, and more, our seasoned designers and engineers conduct dedicated engineer to ensure superior products from the very beginning.

Whether you are a large or small business, we treat you the same. We are committed to providing quality products while providing unparalleled service to help you expand, grow and thrive.

Excellence is in every detail. We adhere to strict quality standards at every step, every process, and are committed to providing you with the highest quality products.

See how Tengjin has grown over the years, from its humble beginnings to becoming a reliable plastic and rubber manufacturer in the industry.

Fred Liu started Tengjin in Guangzhou as an injection molding company specializing in injection mold production. We began to find new methods to ensure affordable and high-quality molded parts.

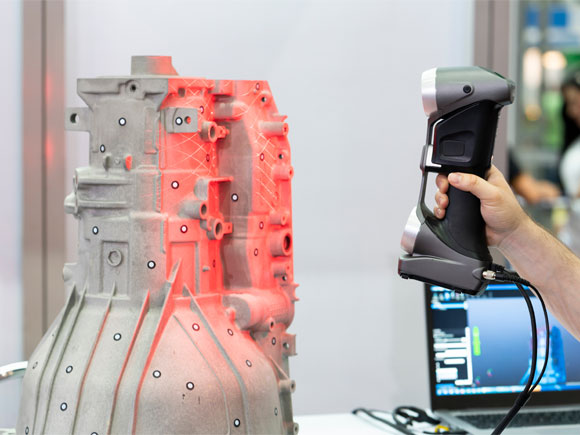

We continued our growth with new investors, focusing on expanding and going global in our production. As we grow worldwide, our quality has even improved. We now offer other molding methods like compression, extrusion, and CNC, besides injection moldings.

To improve quality and efficiency, production machinery like our CNC, EDM, and injection molding machine was upgraded. The upgrade increased production and quality but remained relatively affordable.

Adding the blowing mold method as another molding production line and developing rapid prototyping services pave the path to full automation. With this, our operation increased in output of high-quality products in the market.

Continuing our production after the world crisis and pressing on to provide high-performance plastic and rubber parts on a global scale dedicated to designing rubber and plastic components for industries.

Sustainable materials and business practices make our production efficient and environmentally friendly—reducing waste and our ecological footprint to make a difference. Green production still ensures quality in our products and gives back to the community through efficiency and waste management.

If you’re ready to reduce your time to market, design and manufacture better rubber and plastic parts, reduce risk and improve your profit, Tengjin is the best choice. Let’s talk and get your project started.

Copyright © 2022, Tengjin. All rights reserved. Powered by MML