Making new things possible and better with Tengjin.

Making new things possible and better with Tengjin.

We have an experienced team to fulfill your plastic and rubber parts needs from mold or product development to solving performance and quality issues with existing products. Within our design work, we consider your budget and see how your ideas can be feasibly manufactured into products or mold that are reliable, functionable and serviceable.

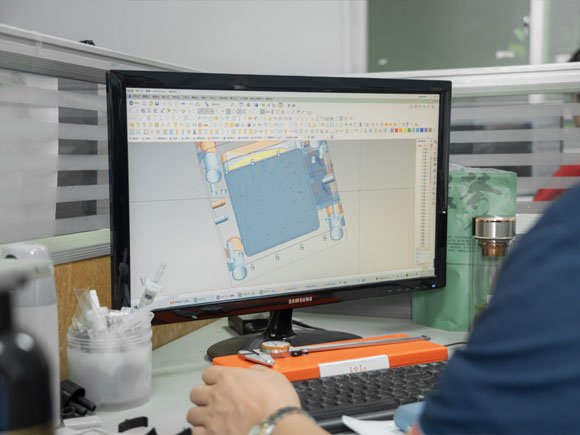

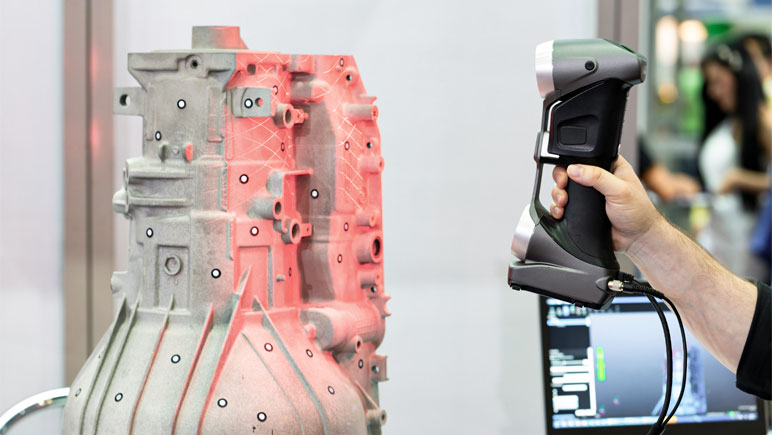

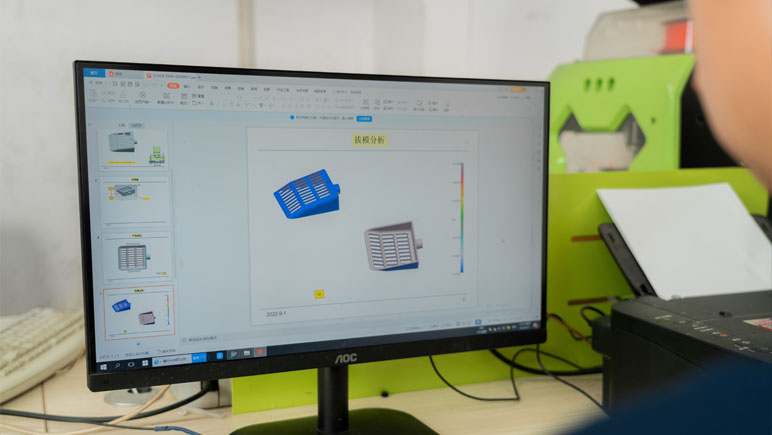

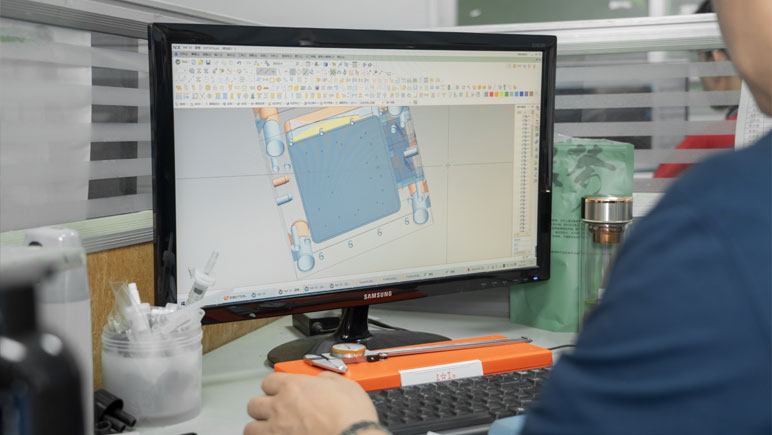

Our designers have mastered the art of CAD design, reverse engineering, DFM and mold flow analysis to realize your drawings, bringing out every detail you have to maximize their usability.

Our design pays attention to your details. As such, we provide samples early on to boost production speed and meticulously consider their manufacturability to ensure premium quality.

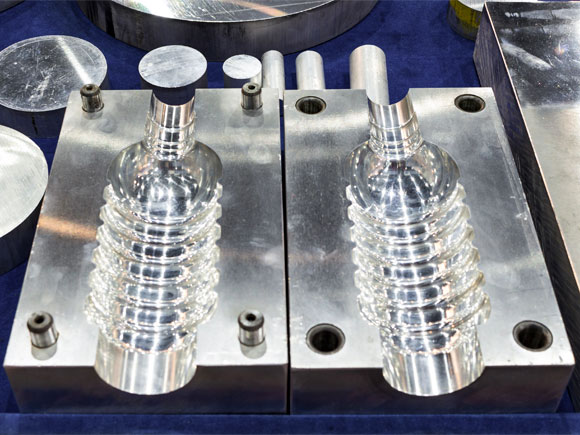

We realize a complete production of plastic injection molds through DFM report, reverse engineering, and mold flow analysis, all made to accurately reflect your design and fit industry standards.

Our design team can validate your product designs to ensure they fit standards and can be produced into accurate products. Ultimately, we work to guarantee the quality and appearance of the finished product.

The rapid prototypes of plastics, rubbers, and metal help products enter the market quickly while encouraging the iteration of newer products.

Our engineers have extensive experience in plastic and lsr injection molding and injection molds. Design and engineering approaches allow for proactive resolution of tooling issues, concerns, or possible issues before fabrication.

We create custom parts and molds that fit your design and come with accurate dimensions that fulfill their applications precisely. Doing so reduces unnecessary product waste and saves on costs.

Applying our experience of various of on demand manufacturing, we eliminate excess material waste and defective output while also decreasing production costs.

By implementing a proper mold flow analysis and DFM report, we prevent errors before we complete the production process, ensuring every product is made easier and safer to use while speeding up the production timeline.

Accurate DFM analysis and mold flow analysis can well analyze the potential risks of molds, custom products, and more in advance, ensuring a low defect rate.

We produce a variety of products, ranging from rubber gaskets and seals to plastic frames, fencing, bottles and medical equipment, all designed to customer’s specifications.

If you’re ready to reduce your time to market, design and manufacture better rubber and plastic parts, reduce risk and improve your profit, Tengjin is the best choice. Let’s talk and get your project started.

Copyright © 2022, Tengjin. All rights reserved. Powered by MML